Manufacturing is not an easy industry to run a business in. In fact, it’s one that’s showing signs of slowing growth and fierce competition. But if you do it well, you can assert yourself an established place and a gap in the market that needs you. So, what do you need to make your manufacturing facility or company a success? The key lies to tackling the different prongs of the business, not just the manufacturing itself. You need the business sense as well as the qualified team. The financial skills as well as sharp maintenance. To top it all, you need to make sure poor safety isn’t killing your business. Let’s take a more detailed look.

Business sense

A lot of manufacturers tend to fail when it comes to looking at their business from an actual business perspective. Sometimes, you need to find someone to act as a salesperson if you don’t have the ability. Other times, it’s about taking the costs and gains of each individual client so you’re not taking on something that will earn you next to nothing. Always keep the strength of the business in mind, not just the quality of services you’re providing.

Safety

It’s one of the most important aspects of running any company and when it comes to running a manufacturing facility, it jumps up a notch. Most manufacturing companies have need of someone hired specifically to fill that role, a safety officer. But make sure you’re following all the other steps you need. Signage around the premises, no faulty equipment and proper training are must-haves. Implement proper safety procedure to reduce the risks to your livelihood down the line.

Maintenance

The safety of your equipment and premises is almost as important as your employees’ safety. After all, faulty parts in the premises can mean losing money and endangering employees. Make sure you have the tools like a flange spreader and soldering to fix any problems. If you can’t manage qualified maintenance, you’ll end up spending a lot more on replacement equipment instead.

Your employees

When hiring employees, make sure they’re perfectly suited to the specifics of their job. But it doesn’t end there. In manufacturing, a lot of training and know-how is applicable to other parts of the process. With the use of cross-training, you can make these applicable employees even more useful. By training them across the board, you’re giving them upward mobility that makes them want to stick with you longer. You’re also gaining an elite team at the same time.

Finances

The manufacturers of today need to be on top of their finances. Loss and lack of LEAN practices in the workplace can lead to all kinds of financial disaster. Budgeting and cash flow are important ways of recognizing what’s going wrong in your business. This isn’t a process to be done alone, but rather by using the expertise of the team you have on the floor. Use their experience and know-how to get real estimates of what it takes to run your business and what changes you can make.

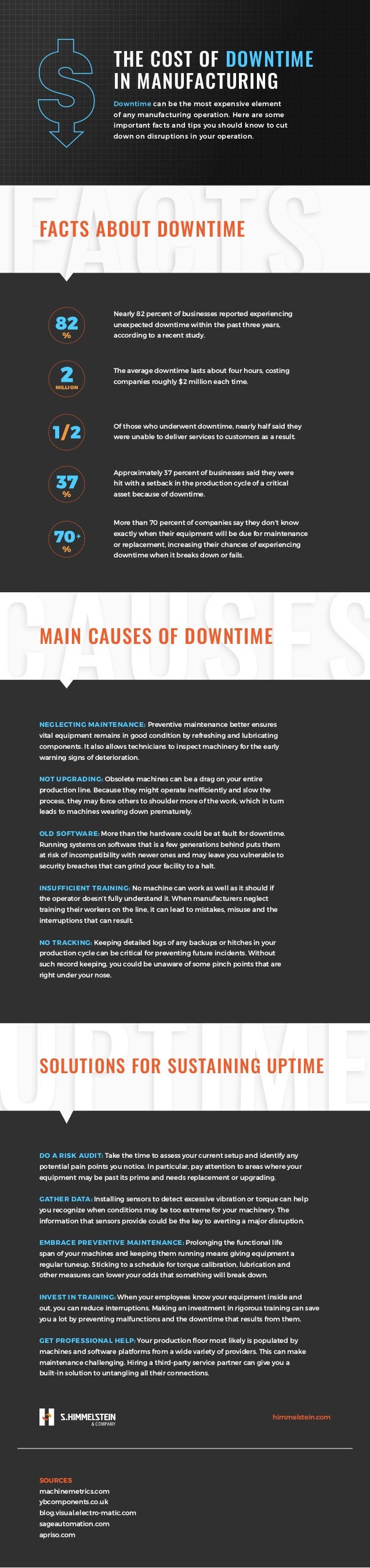

The infographic, below, “The Cost of Downtime in Manufacturing,” was created by S. Himmelstein & Company, a leading manufacturer of torque tranducers.

Be the first to comment